Hangzhou Huaguang Advanced Welding Materials Co., Ltd.

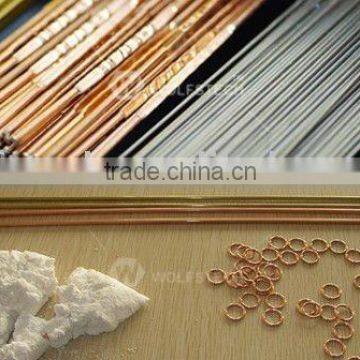

Main Products: Copper-based brazing, Silver brazing filler metals

Home > Company Introduction

Company Overview

Hangzhou Huaguang Welding Materials Co., Ltd. was founded in 1995. Our company is a private science and technology enterprise which specializes in the research and manufacture of brazing and soldering materials and alloys.

Our company covers an area of 20,000m2, with registered capital of 17 million Yuan and has an experienced R&D team headed by professional engineers from Zhejiang University and Harbin Institute of Technology. Our company has strong technical force and advanced imported equipment. Our annual production capacity reaches over 2000 tons.

Our company is one of the large scaled enterprises in this business. Our company was titled as High-Tech Enterprise and Key High-Tech Enterprises of National Torch Plan Projects in 2008.

-

Manufacturer, Trading CompanyBusiness Type

-

1997Year Established

-

10,000-30,000 square metersFactory Size

-

301 - 500 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

301 - 500 People Total Employees

-

Domestic Market Main Markets

-

Port of Shipment

-

Other Welding & Soldering Supplies Main Industry

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.